Understanding Cable Design: Water-Resistant, Waterproof, and Watertight

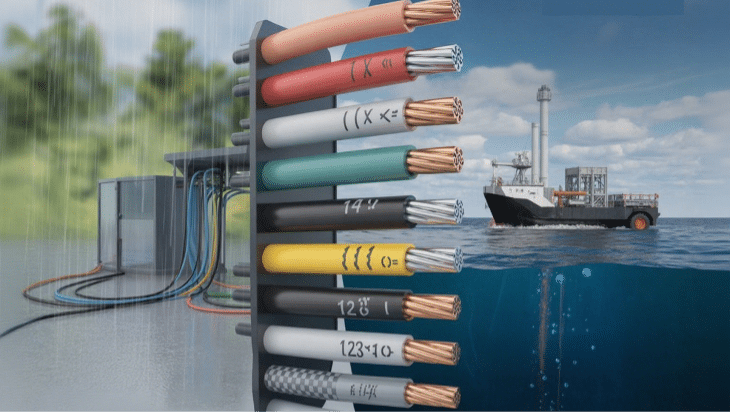

In industrial, marine, and outdoor environments, electrical cables often face constant exposure to moisture, rain, and even complete submersion. Selecting the right level of water protection is critical not only for maintaining electrical performance but also for extending system lifespan and avoiding costly failures.

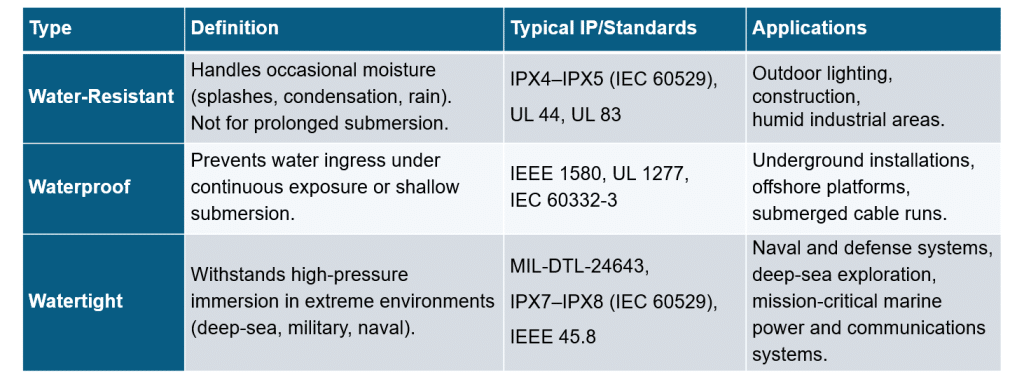

To address these challenges, cables are commonly classified into three protection levels—water-resistant, waterproof, and watertight—each designed to handle specific environmental and operational demands. These classifications are defined by international standards such as IEC 60529 (IP ratings), UL 44/83, IEEE 1580, and MIL-DTL-24643, which establish performance benchmarks for manufacturers and end-users alike.

Cable Classifications at a Glance

Key Industry Standards for Water-Protected Cables

When selecting cables for moisture-prone or submerged environments, it’s essential to understand the governing standards. These benchmarks define how cables are tested and certified for durability and safety:

- IEC 60529 (IP Ratings): Defines protection against dust and water ingress. IPX4–IPX5: Handles splashes and humidity, not immersion. IPX7–IPX8: Built for submersion (up to 1 meter for 30 minutes, or continuous immersion at specified depths).

- UL 44: Specifies thermoset-insulated wires and cables with moisture resistance, used in power and control systems.

- UL 83: Focuses on thermoplastic-insulated conductors designed for reliable operation in humid or outdoor environments.

- UL 1277: Covers Type TC tray cables with added waterproof features, including tests for impact, crush, and water penetration resistance.

- IEC 60332-3: Adds fire-resistant properties to waterproofing, keeping cables functional even under flame exposure.

- IEEE 1580: Specifies marine-grade waterproof cables for offshore and shipboard applications, ensuring long-term insulation integrity.

- MIL-DTL-24643: U.S. military standard for watertight cables, ensuring pressure resistance and durability in naval environments.

- IEEE 45.8: Covers marine shipboard electrical cables, guaranteeing saltwater resistance and reliability for mission-critical systems.

Choosing the Right Cable

The right cable depends on exposure level, operating pressure, and application requirements. Using the correct classification helps OEMs reduce failure risks, prevent warranty costs, and maintain safety compliance.

At VEXOS CMS, we specialize in custom cable and harness assemblies for demanding environments, from medical-grade waterproof solutions to automotive harnesses with 100% end-of-line testing. Our global supply network—spanning China, Vietnam, Malaysia, Indonesia, and the Americas—allows us to deliver cost-effective, certified solutions with speed and flexibility.

Looking for water-resistant, waterproof, or watertight cables that meet stringent international standards?

LEARN MORE FROM https://cms.vexos.com/cable-and-harness-assembly/to build a resilient, agile supply chain with tested, certified solutions tailored to your industry needs.