CASE STUDY: How a Tolerance Correction Reduced CNC Machining Cost by 23.2%

Industry: Industrial Automation

Application: SCARA Robot End-Effector

Component: CNC Machined Aluminum Bracket (6061-T6)

Introduction: A Common but Expensive Tolerance Mistake in Automation Hardware

In industrial automation, precision is critical—but over-specifying tolerances has become a hidden cost driver. Industry research suggests that a significant share of tolerances on CNC parts are tighter than functional requirements demand. This “insurance tolerancing” raises machining time, inspection load, and scrap risk without improving SCARA end-effector performance or alignment accuracy.

The following case represents a typical scenario observed across automation hardware manufacturing.

Project Background

A US-based automation integrator required a lightweight CNC aluminum bracket for a SCARA robot end-effector. The bracket routed signals, supported a vacuum pick-up, and needed accurate alignment across two mounting planes.

Original Requirements:

Material: 6061-T6 aluminum

Process: CNC milling + tapping

Batch size: 200–300 units

Key constraint: mounting-plane alignment accuracy

The Tolerance Issue

The original drawing applied ±0.01 mm tolerances to most surfaces, instead of limiting them to functional mounting features.

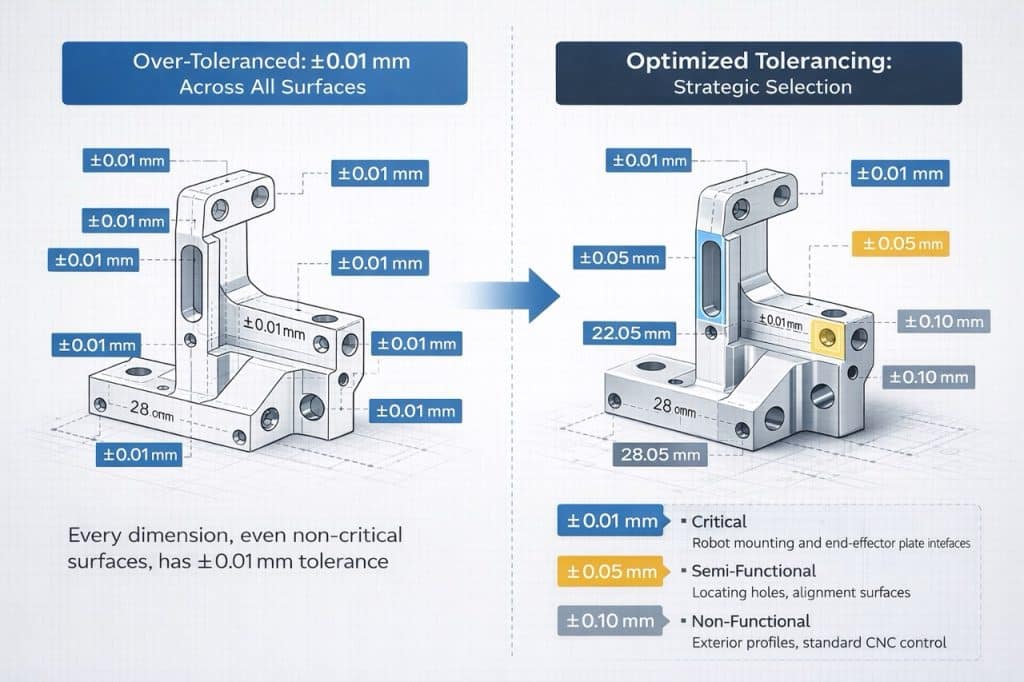

Over-Toleranced vs Optimized Tolerancing

This caused two main issues:

- Cost Impact

Slower machining, tighter toolpath control, custom inspection fixtures, and higher scrap risk increased unit cost by more than 20%. - No Functional Gain

Engineering analysis showed that only two interfaces required tight control:- robot mounting face

- end-effector plate interface

All other surfaces were non-functional for alignment.

The Solution: Tolerance Re-Classification

A design-for-manufacturing (DFM) review re-classified dimensions according to functional needs:

Critical Features: Kept at ±0.01 mm

Semi-Functional Features: Relaxed to ±0.05 mm

Non-Functional Surfaces: Relaxed to ±0.10 mm or reverted to standard CNC tolerances

This preserved robotic alignment accuracy while reducing machining complexity.

Results

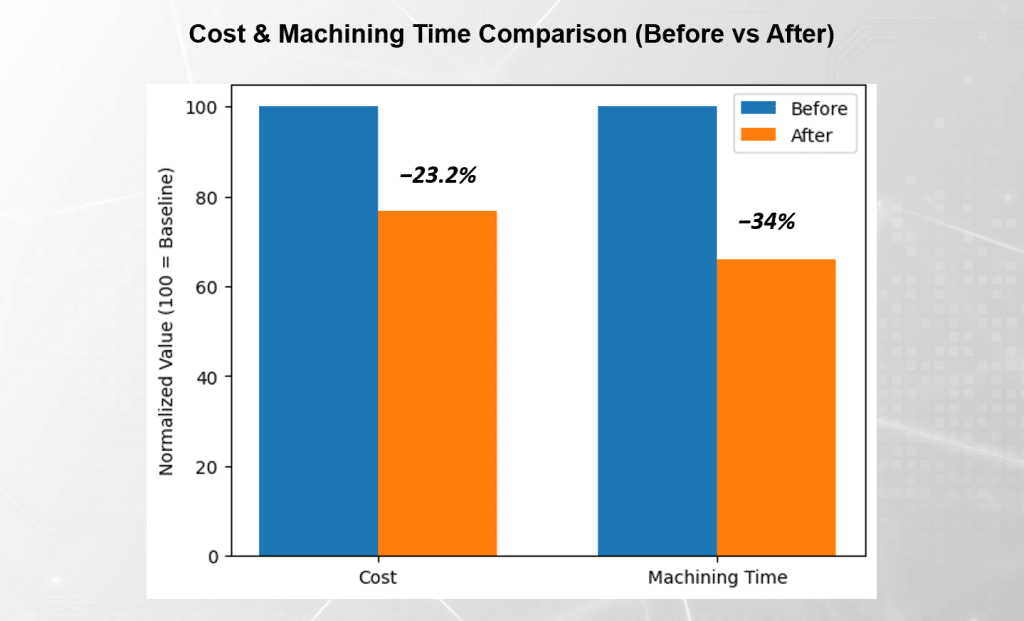

After tolerance optimization, the part achieved:

- 23.2% reduction in CNC machining cost

- 34% reduction in machining time per unit

- 0% change in alignment performance

- Lower scrap and faster QA inspection

The bracket performed identically; only the cost changed.

Industry Insight

Over-tolerancing is widespread in automation hardware. Brackets, EOAT frames, housings, and precision plates often inherit tight tolerances during CAD design stages that do not reflect actual stack-up requirements in SCARA, Delta, or linear-axis systems.

Key Takeaways for Automation OEMs

- Many tolerances are tighter than functional needs

- Early DFM reviews unlock fast cost savings

- Reducing non-critical tolerances does not degrade robot performance

- Savings compound in high-mix CNC environments

Conclusion

For automation and robotics OEMs, tolerance control is both a precision requirement and a cost-management lever. A targeted DFM review can significantly reduce CNC machining costs without compromising functional performance.

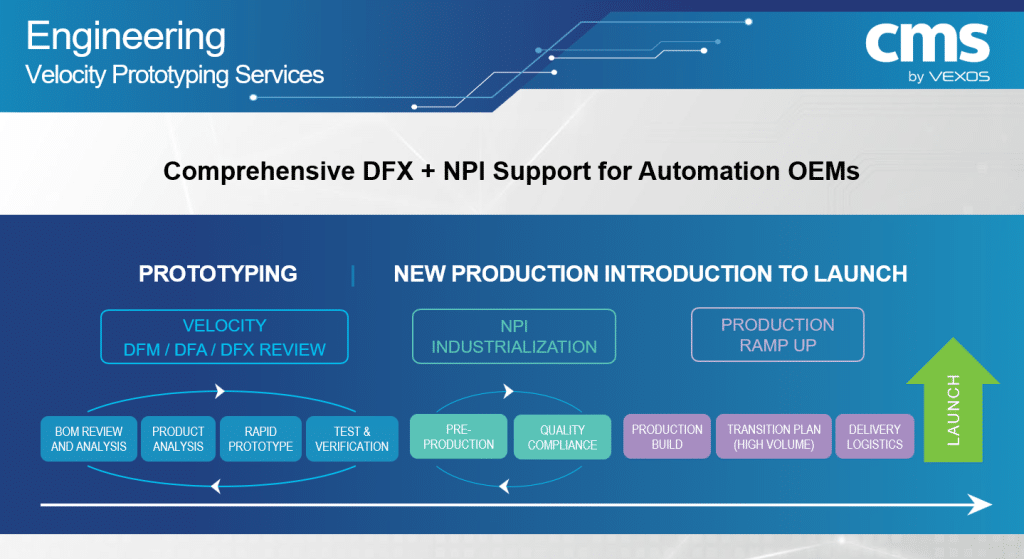

Tolerance optimization, however, is only one dimension. The OEMs that consistently achieve meaningful cost and schedule gains are those that integrate DFX early in the development cycle. If you are evaluating automation brackets, robot EOAT components, or CNC-machined technical hardware, this is where Vexos CMS can help.

Comprehensive DFX + NPI Support for Automation OEMs | Vexos CMS

Vexos CMS supports engineering teams through structured and repeatable DFM / DFA analysis, prototype builds, NPI qualification, and ramp-up execution. For robotics and industrial automation OEMs, this accelerates development while reducing risk and cost.

Contact our engineering team for DFM / DFA support or CNC machining quotations: info@vexos.com