Medical PCBs: Requirements, Applications, and Design Considerations

In the medical industry, PCBs are more than electronic backbones — they directly impact patient safety, device reliability, and regulatory approval. Designing a PCB for medical use requires strict compliance with standards such as ISO 13485, FDA guidelines, and IPC Class 3, but the requirements vary greatly depending on the type of device.

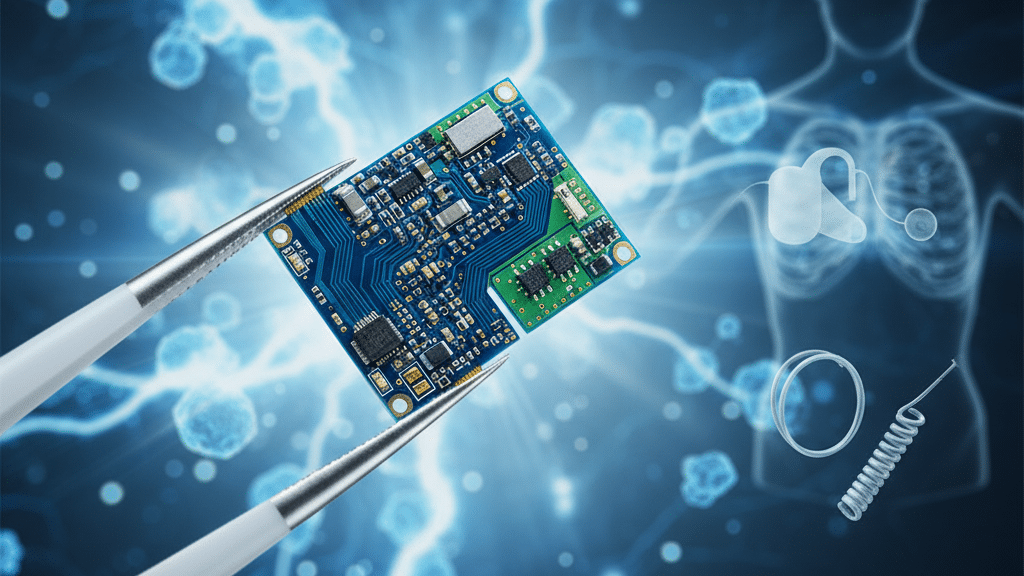

1. Implantable Devices (Pacemakers, Neurostimulators, Hearing Aids)

- PCB Type: Ultra-miniaturized rigid-flex or HDI boards with biocompatible materials.

- Key Requirements: Miniaturization and low power consumption. Long-term reliability (must last 10–15 years without failure). High resistance to body fluids and sterilization processes.

- Design Challenges: Using medical-grade materials (e.g., polyimide flex), ensuring hermetic sealing, and achieving high-density interconnects in very small footprints.

- Cost Consideration: High — due to specialized materials, testing, and extremely low tolerance for defects.

2. Diagnostic Imaging Systems (MRI, CT, Ultrasound, X-ray)

- PCB Type: Large multi-layer rigid PCBs with controlled impedance.

- Key Requirements: High-speed signal integrity for image accuracy. Heat dissipation for high-power circuits. Electromagnetic compatibility (EMC) to avoid interference with sensitive equipment.

- Design Challenges: Precise stack-up design and signal shielding.

- Cost Consideration: Medium to high, depending on layer count and copper thickness.

3. Patient Monitoring & Life-Support Systems (Ventilators, ECG, Blood Pressure Monitors)

- PCB Type: Rigid and rigid-flex PCBs with emphasis on long-term stability.

- Key Requirements: High reliability and zero downtime (critical in ICU settings). Compliance with IPC Class 3 for extended life cycles. Traceability of components for regulatory audits.

- Design Challenges: Redundant circuit design to minimize single points of failure.

- Cost Consideration: Moderate — higher than consumer electronics but lower than implantables.

4. Wearable & Portable Medical Devices (Glucose Monitors, Smart Patches, Portable ECGs)

- PCB Type: Flexible and rigid-flex PCBs for lightweight, compact form factors.

- Key Requirements: Flexibility and durability to withstand repeated bending. Low power consumption for extended battery life. Biocompatibility and comfort for skin contact devices.

- Design Challenges: Thin materials, high reliability under mechanical stress, integration with sensors.

- Cost Consideration: Lower than implantables, but higher than general wearables due to compliance testing.

Special Manufacturing Considerations in Medical PCBs

- Sterilization Resistance: PCBs must survive repeated exposure to autoclaves, radiation, or chemical sterilization.

- Traceability: Every board must have lot tracking and manufacturing history for audits.

- Testing Requirements: 100% electrical testing, burn-in testing, and reliability verification are mandatory.

The medical industry shows how PCB design is application-driven: the same regulatory framework applies, but the choice of PCB type, materials, and processes changes dramatically depending on whether it’s used in a pacemaker or an MRI scanner.

This depth of specialization makes medical PCBs one of the most demanding and high-value sectors for PCB manufacturers.

From implantables to imaging systems, every medical device demands precision, reliability, and compliance. Connect with us to explore PCB solutions tailored to your application: https://cms.vexos.com/pcb

- Important Note on Imagery: The illustrations in this article are AI-generated and are intended to serve as conceptual or supplementary material. Readers should be aware that specific technical accuracy or intricate professional details may vary from real-world components.